Ethanol Producer – Adds Modular D-Boiler

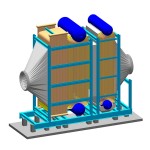

Indeck Keystone Energy received a contract for the supply of one 370,000 PPH / 450 PSIG rail shipped Package Boiler. The 3 piece modular “D” boiler and was shop assembled to minimize site construction cost and schedule. The boiler and auxiliary equipment were delivered and were successfully started up.

Indeck Keystone Energy received a contract for the supply of one 370,000 PPH / 450 PSIG rail shipped Package Boiler. The 3 piece modular “D” boiler and was shop assembled to minimize site construction cost and schedule. The boiler and auxiliary equipment were delivered and were successfully started up.

US Refinery – FCCU Flue Gas Cooler

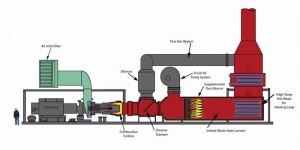

A major refinery in the United States has selected Indeck Keystone Energy, LLC (IKE) to supply a severe duty Fluidized Catalytic Cracking Unit (FCCU) flue gas cooler (FGC). The FCCU FGC’s operate in a highly abrasive and corrosive environment. Indeck has successfully worked with this client multiple times to supply proven FCCU flue gas cooler designs. The boiler and auxiliary equipment were delivered and were successfully started up.

To minimize the installation duration, the superheater and boiler modules were manufactured as assembled modules for setting on the customer’s foundations. Each system consisted of superheater modules integrated into the High Pressure (HP) boiler module, a Low Pressure (LP) Boiler module, and associated ductwork. Client feedback was incorporated in new design innovations based on site specific operating conditions for each design in order to improve access, cleanability , and reliability. Indeck’s design has proven thermal performance and reliability.

From 710,000 lb / hr. FCCU flue gas flow at 1035 º F. and 230 º F. feedwater:

HP superheated steam flow is 68,500 lb / hr. – Design pressure is 750 psig.

LP steam flow is 29,500 lb / hr. – Design pressure is 125 psig

Flue gas design pressure is 5 psig. – Tube and membrane wall construction

Cold Climate Heating and Power – New Coal Fired Boiler Using Indeck Travagrate® Stoker

Indeck Keystone Energy was awarded a contract for the supply of two superheated 120,000 PPH / 600 PSIG Coal Fired boilers with auxiliary equipment for field erection. These systems will be installed for central heat and power at a subarctic climate location in North America . The boilers are being furnished in two phases in order to replace existing 1950’s units without impeding the heating requirements of the plant. The boiler and auxiliary equipment have been delivered and started up successfully.

Indeck Keystone Energy was awarded a contract for the supply of two superheated 120,000 PPH / 600 PSIG Coal Fired boilers with auxiliary equipment for field erection. These systems will be installed for central heat and power at a subarctic climate location in North America . The boilers are being furnished in two phases in order to replace existing 1950’s units without impeding the heating requirements of the plant. The boiler and auxiliary equipment have been delivered and started up successfully.

Indeck is using its time tested and proven Travagrate® stoker with reciprocating feeders and over fire air and ash re-inject system for lower emissions and increased efficiency. The stoker is completely assembled and match marked prior to disassembly to help the field to reassemble. Feeders and stoker drive unit are fabricated, assembled and tested prior to shipment. This is all done in our shop in Erie, PA.

Indeck is using its time tested and proven Travagrate® stoker with reciprocating feeders and over fire air and ash re-inject system for lower emissions and increased efficiency. The stoker is completely assembled and match marked prior to disassembly to help the field to reassemble. Feeders and stoker drive unit are fabricated, assembled and tested prior to shipment. This is all done in our shop in Erie, PA.

Large University Uses High Temperature Hot Water Cogeneration to Reduce CO2 Emissions

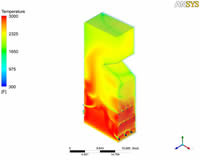

A large university in Canada awarded Indeck Keystone Energy a contract for the supply of our waste heat high temperature hot water generator for use in their combined heat and power cogeneration plant in an effort to reduce CO2 emissions by 50%. The Indeck high temperature hot water generator converts the waste gas stream into 200 MMbtu /hr of hot water heat supplied to the universities’ campus heating system. Indeck’s scope of supply included all equipment downstream of a Solar Titan 130 gas turbine including an integral duct burner and flue gas bypass system for operational flexibility and ability to supply campus heat in cogeneration, supplemental, and heating only mode via fresh air firing. The complete system is currently operating successfully, meeting all performance and emission targets. The fuel once used to heat campus is now used to generate 12 MW of electricity with campus heat being recovered from the combustion turbine’s waste gas.

Coal Fired Boiler For Heating Plant

Indeck Keystone Energy was awarded a contract for the supply of an 80,000 PPH / 750 PSIG stoker fired coal boiler with auxiliary equipment for field erection. The system is installed at a university heating plant as part of an emissions compliance upgrade replacing boilers from the 1950’s. The boiler surpassed all performance and emission goals. The boiler and auxiliary equipment have been delivered and started up successfully.

Steel Producer Converts Waste Gas to Steam – Barge Shipped D-Boiler

A global steel producer awarded Indeck Keystone Energy a contract for the supply of a Blast Furnace Gas fired boiler and auxilaries as part of a project to convert waste by-product gases into electricity at a steel plant in the United States . The boiler design is a shop assembled “D” Type package boiler rated at 350,000 PPH / 1300 PSIG. Indeck managed the logistical move of the shop assembled boiler weighing 1 million pounds. The construction and transportation strategy used by Indeck minimized installation costs and schedule. The boiler and auxiliary equipment were delivered and were successfully started up.

A global steel producer awarded Indeck Keystone Energy a contract for the supply of a Blast Furnace Gas fired boiler and auxilaries as part of a project to convert waste by-product gases into electricity at a steel plant in the United States . The boiler design is a shop assembled “D” Type package boiler rated at 350,000 PPH / 1300 PSIG. Indeck managed the logistical move of the shop assembled boiler weighing 1 million pounds. The construction and transportation strategy used by Indeck minimized installation costs and schedule. The boiler and auxiliary equipment were delivered and were successfully started up.

Correctional Institution Combines Heat and Power using Indeck’s incline HRSG

A correctional institution in the US awarded Indeck a contract for the supply of a Heat Recovery Steam Generator (HRSG) system with auxiliary equipment to generate steam from waste gas. The Incline HRSG reclaims waste heat from a Centaur 40 gas turbine and supplies 19,200 PPH / 135 PSIG steam to the prison for heating and process users. The boiler and auxiliary equipment were delivered and were successfully started up.

A correctional institution in the US awarded Indeck a contract for the supply of a Heat Recovery Steam Generator (HRSG) system with auxiliary equipment to generate steam from waste gas. The Incline HRSG reclaims waste heat from a Centaur 40 gas turbine and supplies 19,200 PPH / 135 PSIG steam to the prison for heating and process users. The boiler and auxiliary equipment were delivered and were successfully started up.

Oil Sands Project – Adds 3 Packaged Boilers

Indeck Keystone Energy supplies three new 230,000 PPH / 1132 PSIG packaged “O” type boilers with auxiliary equipment to site in Alberta , Canada . Indeck had already provided two boilers for Phase 1 of the project, these boilers were designed to fire natural and mixed gas and develop saturated steam for injection into horizontal wellheads to loosen and recover bitumen for refining into heavy oil (SAGD process). The boiler and auxiliary equipment have been delivered and start up was a success.

Indeck Keystone Energy supplies three new 230,000 PPH / 1132 PSIG packaged “O” type boilers with auxiliary equipment to site in Alberta , Canada . Indeck had already provided two boilers for Phase 1 of the project, these boilers were designed to fire natural and mixed gas and develop saturated steam for injection into horizontal wellheads to loosen and recover bitumen for refining into heavy oil (SAGD process). The boiler and auxiliary equipment have been delivered and start up was a success.